Laser Overlay/Hard facing

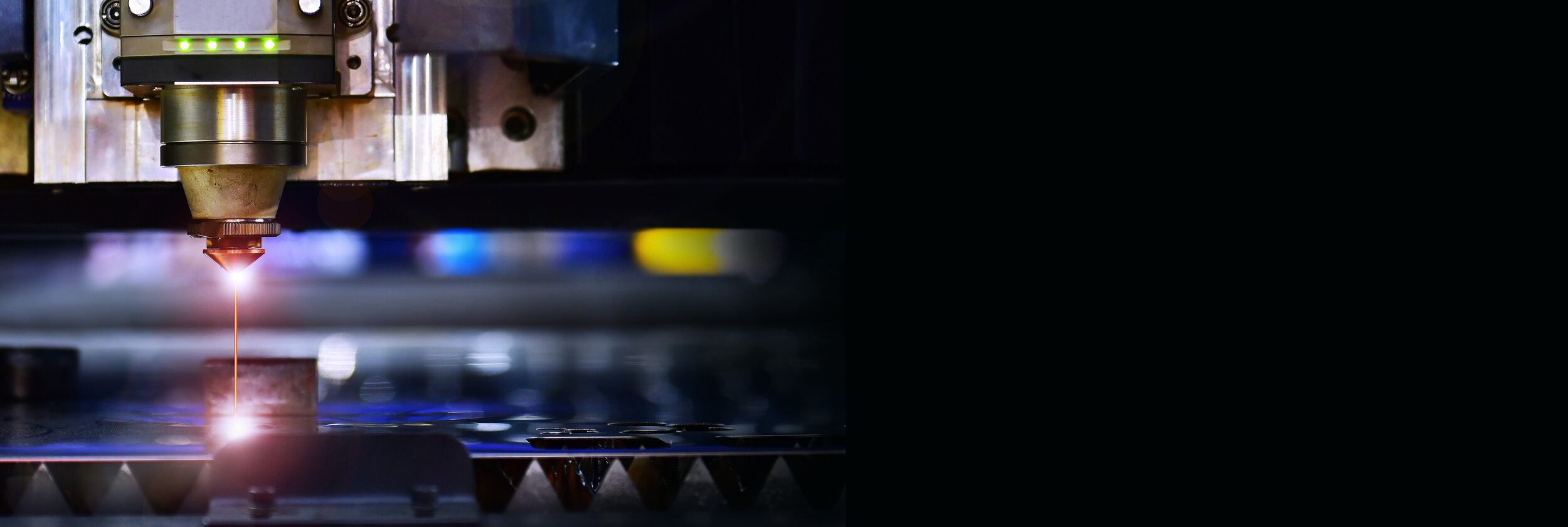

Laser Cladding or Laser Hard Facing is a processing technique used for adding one material to the surface of another in a controlled manner. A stream of a desired powder is fed into a focused laser beam as it is scanned across the target surface, leaving behind a deposited coating of the chosen material. This enables the applied material to be deposited selectively just where it is required.

Knust-Godwin’s laser hard facing & cladding applies tungsten carbide powder to non-magnetic, inconel or low carbon steels by using a laser welding beam. It produces a very high hardness, wear resistant coating with minimal heat input.

Knust-Godwin has extensive Laser Overlay (Hardfacing/cladding) capabilities. We can accommodate parts up to 18 in. OD and 216 in. in length.

Carbide Overlay for Wear Resistance

Laser Overlay Process